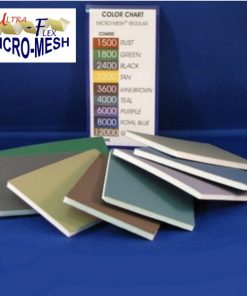

Micro-Mesh Sheet (12 x 6) Regular

Micro-Mesh Sheet (12 x 6) Regular – 305mm x 150mm

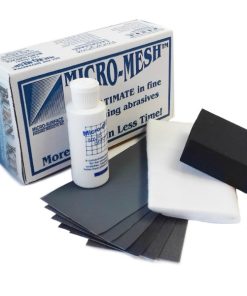

Ideal for making your own emery sticks because it easily bends without breaking.

Can be used effectively wet or dry because the fabric backing is a lot stronger than paper.

Regular is suited to plastics, fibreglass, lacquers, gelcoat, cast polymers, acrylics, softwood, composites etc. Or for final finishing after using MX grade.

Grits start at 1500 which is equivalent to 400g wet and dry paper.

Micro-Mesh Benefits

* Better Surface Contact

The crystals in the conventional abrasives are locked at irregular heights and at random angles. Many never touch the working surface. The Micro-Mesh® system allows the crystals to move – depressing to seek a common level – while rotating their planing chips into alignment. Consequently this creates a smooth shaving action rather than gouging and abrading the surface – an ultrafine scratch pattern results.

* Larger Crystals

The unique ‘Floating Suspension’ of Micro-Mesh® crystals allow us to use relatively large grit to produce super finishes. Micro-Mesh® removes the peaks of the previous scratch pattern without gouging deeper channels.

* Less Loading

Using larger crystals leaves a large valley between crystals relative to the very fine particles removed. These fine particles will fall free of the crystals and clear of the freshly worked

surface.

* Reduced Friction

Much of the heat generated during conventional sanding comes from abraded particles loading the abrasive. This heat can

actually weld the abraded particles back onto the workpiece, creating a false surface. At some future time these particles may come loose, causing part failure. With Micro-Mesh® high heating and welding just can’t occur, assuring surface integrity.

* Longer Life

By avoiding the heat producing friction that can fracture and destroy crystals, Micro-Mesh keeps its superior properties longer – up to 15 time longer – than ordinary abrasives.

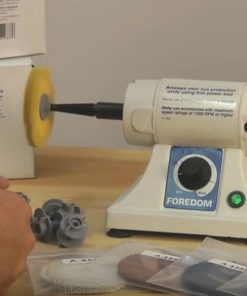

Can use wet or dry. Using wet will prolong life and flush out metal waste, keeping Micro-Mesh® cleaner. Best results will be achieved when using Micro-Mesh® with light pressure and/or at low rotational speeds.

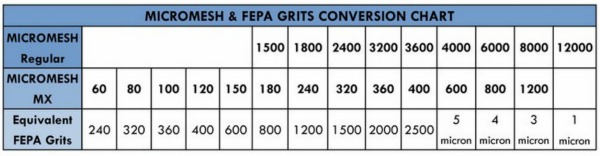

Micro-Mesh Grits

Micro-Mesh works a bit differently from standard abrasives, use this chart to choose the grit you require by comparing to standard FEPA grits.

For Engineers

Regular sheet is great for getting high shine, you may require the MX grits to start the process particularly for surgical instruments, engine components, knives etc

Sheet is useful because it can be used in so many ways. it can be stuck to blocks, used flat or by hand.

For Jewellers

Regular grades are excellent for jewellery as they go up to very fine grits which will actually polish. The sheet is very useful as it can be stuck down to the bench for flat lapping or even stuck to a coffee stirrer for getting right into tight spots.

Reviews

There are no reviews yet.