What Tools do I Need to Polish Jewellery?

Building Your First Polishing Tool Kit

What tools do I need to polish jewellery? Your finishing & polishing tool kit is a vital consideration when you start producing finished pieces. Finishing is often an overlooked area of study with a lot of courses only offering basic information at best. I certainly found my knowlege when I left unisversity didnt quite get me the results I saw on other peoples work at shows. It can be really frustrating when scratches still show and the shine just isnt happening.

There really are only a few items needed to get you started.

How you tackle your tool collection depends on how you are going to polish, by hand or by machine.

It is ok to start polishing by hand and you’ll get adequate results but adding a bit of power in the form of a pendant drill or micromotor will help massively!

If you have the space a bench polisher would eventually be really handy. You can get good results without but it does speed things up which is pretty essential if it is a business for you.

Finishing by Hand

After deburring and smoothing with a needle file you’ll need to smooth the surface further and remove all file marks. Traditionally it is done with Wet & Dry paper moving up through the grits from 500g to around 1200g.

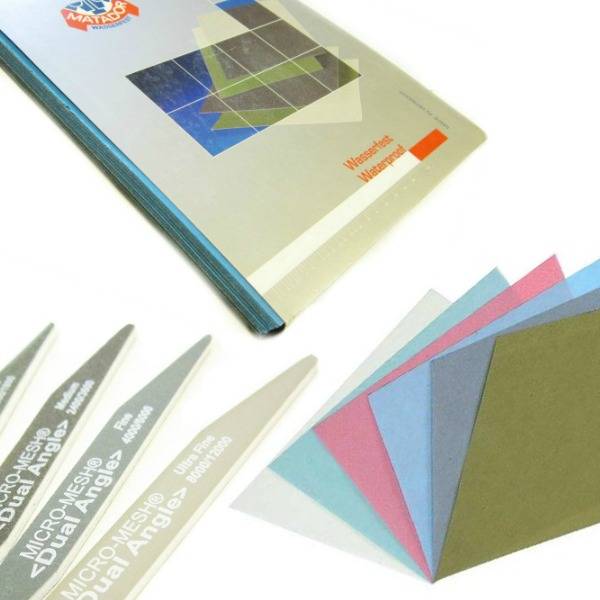

3M polishing papers are very popular with beginners as they are just so easy to use! They are often the subject of jewellery making blog posts. Arguably though I would say that micromesh is a superior longer lasting product.

You can speed things up and keep your tool kit very simple with Micromesh in sheet and flexifile form. Starting with just a 4-way flexifile you can actually go from coarse sanding through to a high gloss finish. If you want minimal tools this really is your best call! I like to pair it with a 100/150mx file for initial smoothing and shaping, though coarse it is possible to start polishing with mops and compound after using this file.

Have You Got Polishing Equipment?

As a beginner or student you may well have access to equipment for polishing. Normally in the form of a pendant motor or if you are lucky a micromotor!

If you’d like to invest in your own equipment you do have some nice options available.

Foredom SR Pendant Motor – If you’d like a classic pendant motor then we’d always recommend a well respected Foredom. Pair with the H.20 quick-release handpiece to make changing mops super speedy. We do also offer an economy option in the very sturdy LY128 it always proves a popular machine for jewellers.

209 Strong Micromotor – a compact system that is portable and quiet. Ideal for home use. The advantage of a micromotor is the thin cord which is light and flexible and produces very little vibration.

Rotary Finishing

Essentially any tool that spins is rotary, this speeds up polishing immeasurably. The results will also be better with the right tools. It is possible to keep these tools to a minimum also. As a basic kit I would recommend the following;

- Mounted felt bobs for polishing inside rings and getting into nooks and crannies.

- Mounted Stitched Mops for removing scratches and for polishing.

- 3M Radial Discs in yellow, blue, peach & light green for textured pieces, findings etc.

- Cotton Yarn mops for the final buff.

Don’t Forget…

You will also need compound! Compound is effectively abrasive grit and wax carrier.

There are two stages of compound (some people like a 3rd stage but its not essential)

Cutting – Removing lines put in by files and abrasive papers and flattening the surface ready for…

Polishing – The final stage, you should have a pretty good finish before you get here, it literally just takes out any fine swirling or scratches from the cutting compound.

We would recommend as a very simple start, Tripoli (cutting) and Rouge (polishing) which are traditional and effective.

4 x 1” bars are about the right size and are the most cost effective option.

However if you would like to start as you mean to go on Menzerna is the best and will last you.

456G (cutting) this is a really nice coarse compound and will work well straight after using a 100/150mx micromesh file leaving a very bright finish.

P175 (yellow metals) M5 (white metals) Polishing – it is not necessary to have both P175, will do both yellow and white metals. M5 is slightly finer.

So there you have it a simple low down of the basic kit needed to start finishing your jewellery.

The next step from here is setting up a bench polisher with mops and compound. You can improve your finish again and speed the process up.