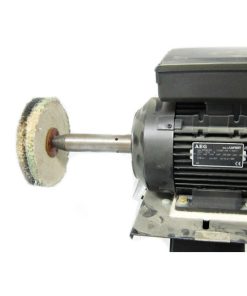

The Eneska Micromotor system is a very powerful electric rotary tool.

This Micromotor system has been especially designed to work better than any Air driven pneumatic tool. Designed to be used with carbide milling cutters for deburring and cleaning.

Air driven pneumatic tool VS The New ENESKA Micromotor 600

- RPM and Speed control: The Eneska Micro offers constant variable speed control from 1,000 to 60,000 RPM with constant torque. Air tools generally run at 35,000 RPM, furthermore they loose torque when the speed is decreased. Using the correct speed on a tool is important for safety and to optimise tool use. For example abrasive tools tend to wear very quickly if they are used to fast. Another factor when using burrs using the faster optimum speed will aid with smoother cutting. The Eneksa system also offers a visual digital readout of the speed so the operator can see exactly what speed the tool is running at.

- Vibration and white finger risk: Micro motor system offer far less vibration – the Eneska 600 offers <2.5m/s2 which is a very smooth running and low vibration.

- Power and Torque: With 280Watts and 7.8N/cm2 the Eneska 600 is more powerful and more torque that most leading air tools. (NSK 601 Has 3.9 to 5.8N/cm2)

Safety Features :

- Air tools generally are fitted with no safety features. The Eneska system will cut out if the collet is not closed correctly. The motor will shut off if the motor is put under too much pressure. the Eneska has several error codes which allow the user to understand what is wrong with the tool.

- Using a foot control is a feature which is not always available for air tools. Using a foot control to start and stop the tool enables quick and safer use of the machine.

Applications for the Eneska Micromotor 600:

- The versatility of the tool allows many different heads/hand pieces to be used with it. All NSK and older ENESKA tools are all compatible with this new control box.

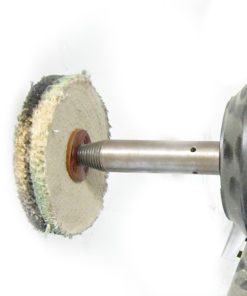

- Mould tool polishing – tools and dies for plastic or composites material.

- This tool is very popular for foundry work as the extra speed is suitable for cleaning and finishing cast items with burrs.

- precision engineers for edge breaking, cleaning, deburring, polishing. – Any component from titanium, steel, iron, chrome, copper, aluminium, brass, gold and silver. sub-contract engineers or precision components for any industry.

- finishing any machined, ground, pressed, cast any metal or plastic item.

Compatible with all NSK and Eneska range: ENESKA motors and headpieces