Decorative Finishes for Precious Metal

Shiny is not the only way! A standard commercial finish is normally a high shine because it is easier to maintain.

A satin or textured finish will often burnish up over time particularly on rings and moving parts.

This considered, the example picture left shows how a contrast of matt and bright areas add life and interest to work.

The matt finish of the mens band at the base was created with abrasive nylon mops. The wearer is a surfer so it will receive heavy wear most likely resulting in a fairly matt finish if worn day to day.

Abrasive Nylon Mops

Mounted nylon wheels are one of the simplest ways to add texture using a rotary tool. It works best to use a finer grade first then finish with a coarse grade with the desired result. We can recommend Green followed by HDMA for the sort of effect as in the above example.

Mounted Abrasive Nylon

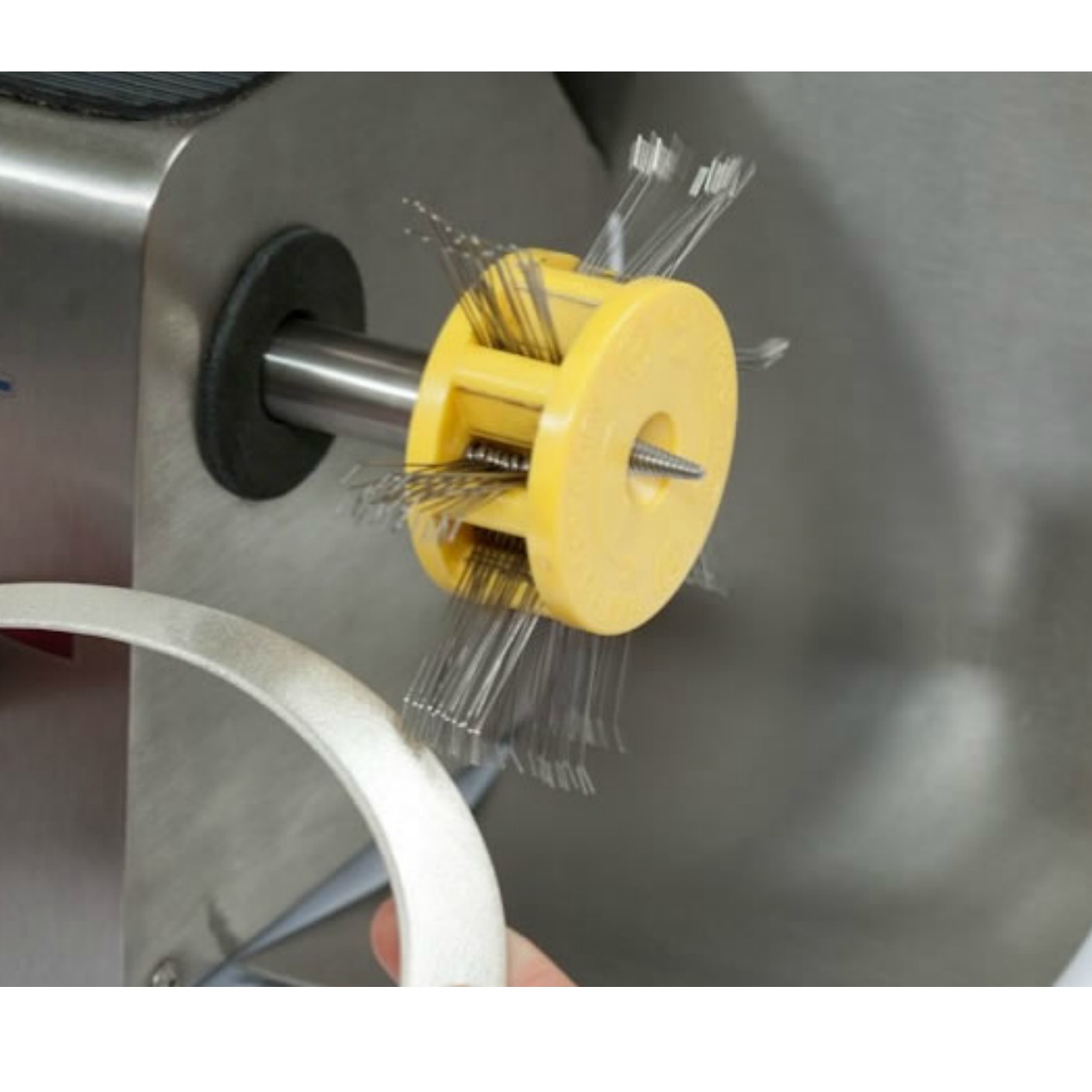

Jewellers Finishing Wheels

These wheels are extremely poplar for giving a really even finish. Also made from abrasive nylon these are used on a bench polisher.

Interestingly they are really good for cleaning up castings particularly the supercut!!

View Nylon Finishing WheelsA Heavier Satin Finish

This ring by Justin Duance shows the difference between a polished finish and a heavy satin finish created with a flick wheel.

The effect is much deeper than an abrasive nylon finish and will last longer. This particular ring was texture with the o.6mm minimat flick wheel.

The look is more akin to shotblasted finish in depth. Often it is called frosting and the wheel called a frosting wheel.

MiniMat Flick Wheels

Minimat wheels are used with a pendant motor or micromotor, these can be a good place to start and ideal for smaller pieces. Eye protection is essential.

View MiniMat Flick Wheels

MaxiMat Flick Wheels

Maximat wheels are used with a polisher and often work better for larger pieces and can be slightly more uniform. Eye protection is essential.

View MaxiMat Flick Wheels

Hammered Finishes

A hammered finish is a longer lasting finish again. Depending on the surface quality of the hammer it can be a bright or a dull effect. Often the hammer face is textured to impart that surface onto the metal. The example to the left is a shiny plain hammer whilst the example below of a specially textured Fretz hammer is much more matt.

Resurfacing/ Polishing Steel Hammers and Tools

Hammers and other steel tools get tired and damaged. It is easy to sand them back using wet and dry paper and polish again using steel polishing compound. A perfectly bright hammer will give a bright hammered finish.

The pink and black small compound bars we sell are ideal for steel tools!

View Polishing Compound

Polishing Hammered Textures

You have to be careful when polishing texture not to soften the effect. The best tool for the job is a radial bristle wheel, depending on if it is a matt or polished finish you require you can choose the right grade. The bristles get down into detail, even stamped letters to some extent.

View Radial Discs