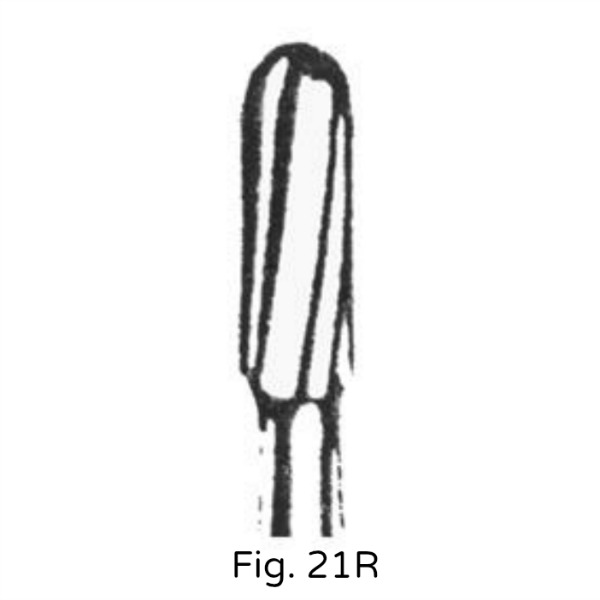

Micro Carbide Burrs Domed Fissure

Micro Carbide Burrs Domed Fissure (Fig. 21R) on 2.35mm Spindle

- Carbide burrs are used for a wide range of stock removal and grinding operations.

- These small burrs on 2.35mm shanks are particularly suited to small detailed work, as a result they are very popular with jewellers.

- They are useful on a wide range of materials, including hard ones such as metal, ceramic, plastics and even wood.

- Plain Cut is for general purpose fluting, as a result the second most popular cut.

- Carbide is commonly used in deburring and for engineering. It offers better long term performance than other materials such as HSS (High Speed Steel).

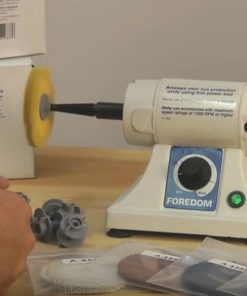

- Carbide burrs need to be used at relatively high speeds.

- Ideally suited to use with air tools, flexible shaft systems and micromotors.

For Engineers

Carbide burrs are an essential tool for removing burrs on machined parts and cutting. Carbide lasts well at the high speeds often required.

The 2.35mm spindle is unusual for engineers, do check that your tool will take this size. A chuck handpiece should be able to clamp down to this size.

For Jewellers

Often jewellers use HSS (High Speed Steel) burrs which do the job but become blunt very quickly. Carbide burrs will last longer and offer better accuracy.

These burrs are on 2.35mm which is ideal for jewellers.

Reviews

There are no reviews yet.